The potential of thermography

Thermographic temperature detection systems, used for fire protection, are currently one of the most reliable prevention technologies, as these provide great anticipation for the onset of causes of fire.

Thermographic temperature detection systems, used for fire protection, are currently one of the most reliable prevention technologies, as these provide great anticipation for the onset of causes of fire.

These technologies are based on a contactless temperature reading, that detects an abnormal increase in temperature and promptly resolves it before ignition values are reached.

Thermographic systems can also be used effectively in outdoor areas where other traditional detection systems are difficult to employ (inefficient).

Thermography anticipates fire detection

Most traditional fire detection systems currently on the market are normally activated when the ignition temperature is reached.

As stated in the regulations in force for fire and safety protection the reaction and intervention time to effectively activate fire risk shall be prompt and responsive.

Additionally, the thermographic system for prompt detection of ignition allows for identification and recognition of the ignition itself in advance anticipating its significant rising.

Thanks to this “time advantage”, it is possible to activate compensatory measures to prevent the onset of the chemical oxidation reaction that would result in combustion.

These small-scale measures are characterized as predictive or organizational maintenance operations and not as fire protection actions.

Act before ignition

The graphic represents the phases that occur in the generation of a fire, starting from the ignition phase.

Thermographic detection already acts effectively in the phase prior to ignition.

Therefore it is possible to effectively resolve critical issues before the ignition phase is even reached.

When properly arranged, traditional detection systems spot the presence of the ignition source and in most cases intervene once the fire has already reached the growth phase.

The compensatory measures written in the company's emergency plan shall be adopted immediately starting at the exact moment of ignition; if they are not executed in time, the exponential growth and the magnitude of the fire’s effects are not effectively managed.

On the other hand, the thermographic detection system is able to operate in a temperature range not yet associated with actual fire risk, thus increasing the time that elapses between the generation of the alarm signal and the activation of the company's firefighting systems.

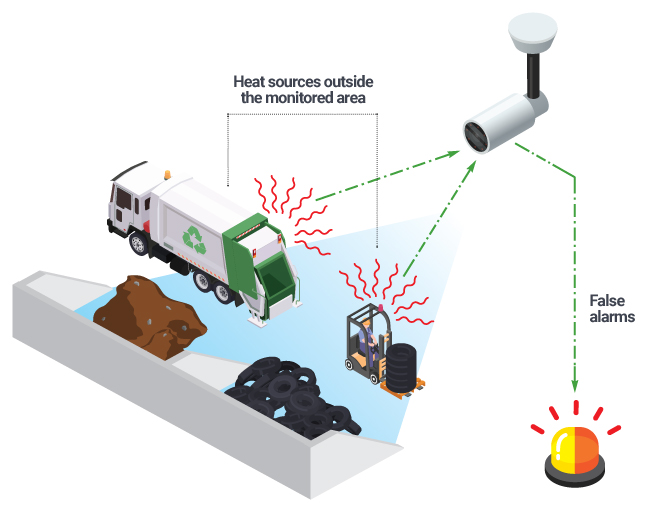

The generation of false alarms

When the thermographic analysis is entrusted exclusively to the control software installed on a single thermal camera, the detection system can generate frequent false alarms, caused by temporary external elements that are not an integral part of the system to be monitored.

False alarms linked to the presence of hot elements (operating vehicles, plant elements, personnel, etc.) that are not differentiated by the thermographic system are the main cause of unjustified interruptions of the production process, which might discourage the choice of this safety system.

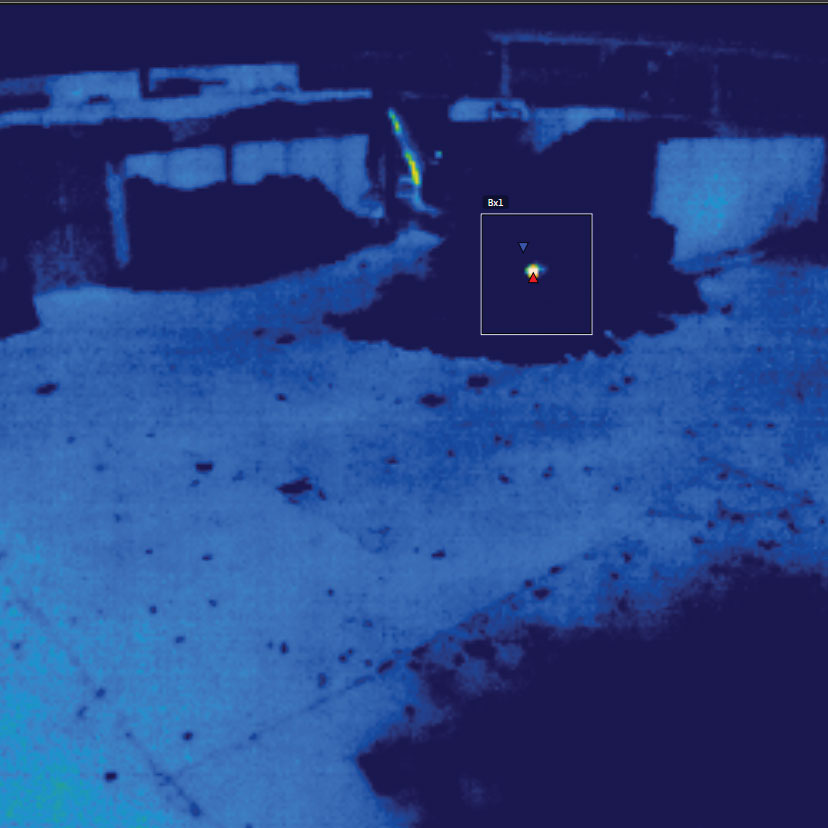

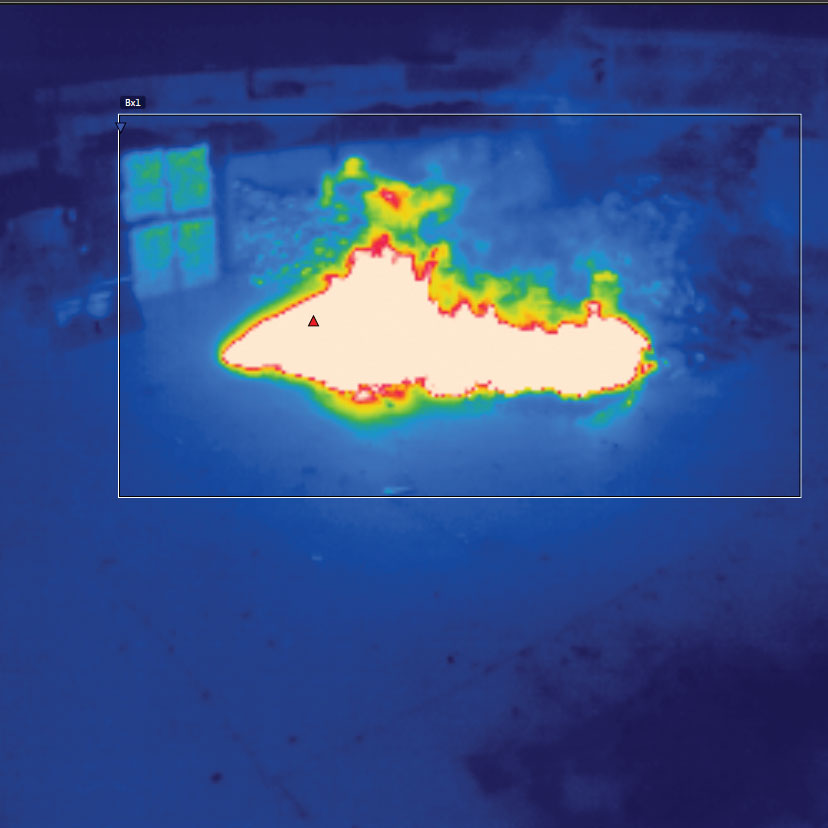

Ignition sequence detected by thermography

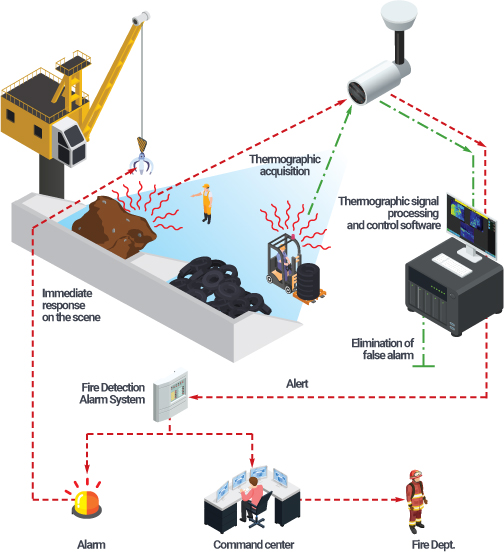

Mozzanica's solution to eliminate false alarms

The thermographic system developed by Mozzanica can process images detected by radiometric thermal cameras with specific temperature ranges, resolutions and optics depending on the type of monitoring, allowing to recognize of potentially dangerous thermal variations before ignition occurs, as well as exclude heat sources not related to the process.

The dedicated proprietary software can simultaneously collect to manage up to 32 thermal cameras, which are set individually according to individual needs.

The Mozzanica integrated predictive thermographic system

The system is constantly connected to an IRAI EN 54 fire control unit linked to a 24/7 command center that is UNI EN 50518 certified, to allow the proper management of alarm transmission procedures and, when necessary, the automatic activation of active protection systems (fire protocols).

The rigorous routine and extraordinary maintenance plans of the entire system, including the necessary and mandatory preventive periodic checks, guarantee the efficiency of the entire fire safety management system.

It's universal

The thermographic detection system can be used in several industry or service activity both in fire protection and in the safeguarding of company assets, in the continuity and control of the production process and in preserving the company's image, specifically from an environmental perspective.

The thermographic detection system can be used in several industry or service activity both in fire protection and in the safeguarding of company assets, in the continuity and control of the production process and in preserving the company's image, specifically from an environmental perspective.

It's evolved

Mozzanica provides thermographic system integration with its exclusive IoT technology See.iT which offers a remote monitoring and diagnostics service.

Mozzanica provides thermographic system integration with its exclusive IoT technology See.iT which offers a remote monitoring and diagnostics service.

Furthermore, the systems are feasible to integrate with:

- automatic extinguishing systems

- fixed fire protection systems

- robotic automatic pan-and-tilt monitors.