Oxygen reduction systems for fire prevention

Mozzanica & Mozzanica has introduced a new ecological fire prevention solution based on controlling the atmosphere of the environment to protect, in accordance with UNI EN 16750.

Oxygen reduction technology has already been widely used for decades in controlled atmosphere plants to store food (mainly fruits & vegetables) to avoid oxidation processes, as well as in the preservation of valuable artwork; it now finds its natural place in the firefighting sector too.

An innovative solution with zero ecological impact, which is certified according to the highest standards.

It can actually be considered a preventive solution, unlike other classic firefighting systems, as it is based on making the atmosphere inert to a level where combustion cannot occur, eliminating the possibility of igniting fires thanks to the constant monitoring and control of the ratio between oxygen and nitrogen in the environment to protect.

Controlled atmosphere plants

The oxygen reduction technology was developed by Mozzanica in partnership with Fruit Control Equipments, an Italian company who is leader in the production of controlled atmosphere technology for food with a wide and long term know-how.

The oxygen reduction technology was developed by Mozzanica in partnership with Fruit Control Equipments, an Italian company who is leader in the production of controlled atmosphere technology for food with a wide and long term know-how.

O2

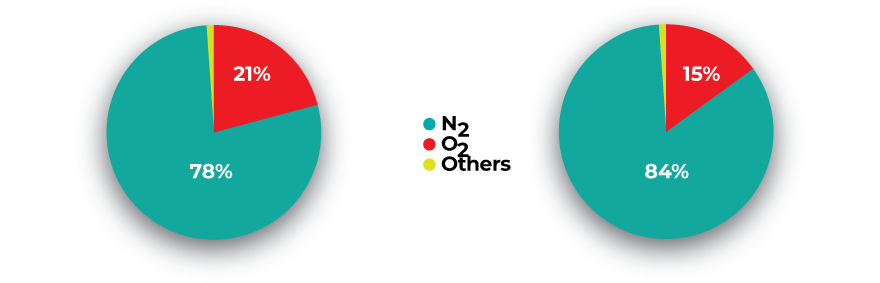

Oxygen is a gas that makes up 21% of the earth's atmosphere and is the main combustive agent in the combustion process.

N2

Nitrogen is a gas that makes up 78% of Earth's atmosphere and is inert, colorless, odorless and tasteless.

Atmospheric air

Consisting of a mixture of oxygen (21% O2), nitrogen (78% N2) and other elements in smaller quantities, it can facilitate a combustion reaction due to the presence of oxygen.

Hypoxic air

It consists of a mixture of a higher concentration of nitrogen (84% N2), a reduced quantity of oxygen (15% O2) and other elements in minimal amounts, which inhibit a combustion reaction.

An ecological solution from the atmosphere

ORS (Oxygen Reduction System) fire prevention is an economically and advantageous solution because it uses atmospheric air for nitrogen production through a Nitrogen Generator without the needs to be supplied like the chemical gases.

Nitrogen is produced on-site by separating compressed air molecules by consinstency, which are treated and filtered as required through mechanical membrane filters or active carbon that separate oxygen from nitrogen.

Oxygen is returned to the atmosphere, while the nitrogen produced is stored in gaseous form to meet the different consumption needs.

A - Absorption: At high pressure, the oxygen molecules, CO2 and aqueous vapor remain trapped in the pores of the active carbon while the larger nitrogen molecules are forced to proceed forward.

B - Regeneration: The pressure is reduced to the atmospheric level. In this way the release of oxygen molecules occurs, which are eliminated and released into the atmosphere.

The system operates preventatively by generating a self-extinguishing protective atmosphere in the environment, consisting of an altered mixture of oxygen + nitrogen that inhibits a fire from igniting.

Furthermore, it is an ecological solution that is completely effective and economically advantageous because of the ease of installation.

The system uses smoke detectors and oxygen concentration detectors in the environment that autonomously regulate the production of nitrogen through PLC and release it into the environment to keep a constant balance between the gases with the right level of hypoxia.

It is an extremely reliable and safe solution thanks to the absence of high-pressure cylinders, with minimal installation and maintenance costs, in compliance with European regulations 97/23/CE PED.

Total prevention for high-risk environments

The ORS prevention system is characterized by its ability to operate in particularly high-risk areas or in highly complex situations, where traditional firefighting systems cannot guarantee a sufficiently high level of safety or are not compatible with the quality standards that the environment to protect requires.

Heritage protection

The oxygen reduction system is particularly suitable where technical, architectural or aesthetic constraints do not allow the installation of conventional firefighting systems, or in specific settings where the assets to protect have a very high economic and/or cultural value, such as historical archives and/or museum areas, where other fire protection systems would cause significant damage to the property.

Advantages of ORS technology

- Complete elimination of all fire hazards

- Zero environmental and aesthetic impact

- Simplicity of design and implementation even in complex settings

- Safeguarding of protected material

- Minimal installation footprint

- Continuous system monitoring

- Extremely convenient for large spaces

- No storage of tanks

- On-site production of the inert gas

Main applications

- Automated warehouses

- Intensive warehouses

- Cold rooms

- Data centers

- Archives and deposits

- Refrigerated warehouses

- Vaults

- Pharmaceutical warehouses