Thermography

applied to waste

disposal facilities

Thermographic systems with early temperature detection used for fire safety are currently one of the most reliable technologies in the field of fire prevention in waste treatment and disposal plants, as they are able to identify the onset of the beginning of a fire well in advance, allowing for its immediate extinction.

Based on a contactless temperature reading, it is possible to detect an abnormal increase in temperature and promptly resolve it before ignition values are reached.

The graphic represents the phases that occur in the generation of a fire, starting from the ignition phase.

Predictive thermographic detection makes it possible to act effectively in the phases that occur before ignition.

As a result, critical issues can be resolved effectively before the ignition phase is even reached.

In addition, thermographic systems are not influenced by light and hardly at all by atmospheric conditions; therefore, they can be used effectively, even in outdoor areas, where other traditional detection systems would be ineffective.

Recognizing the start of a fire in advance

Most traditional fire detection systems currently on the market are usually activated only once combustion is already in progress, with the presence of smoke and flames. (after photo 6).

In these cases, it is difficult to control the propagation and extinction of the fire since this activity is normally entrusted to internal firefighting teams or a firefighting brigade.

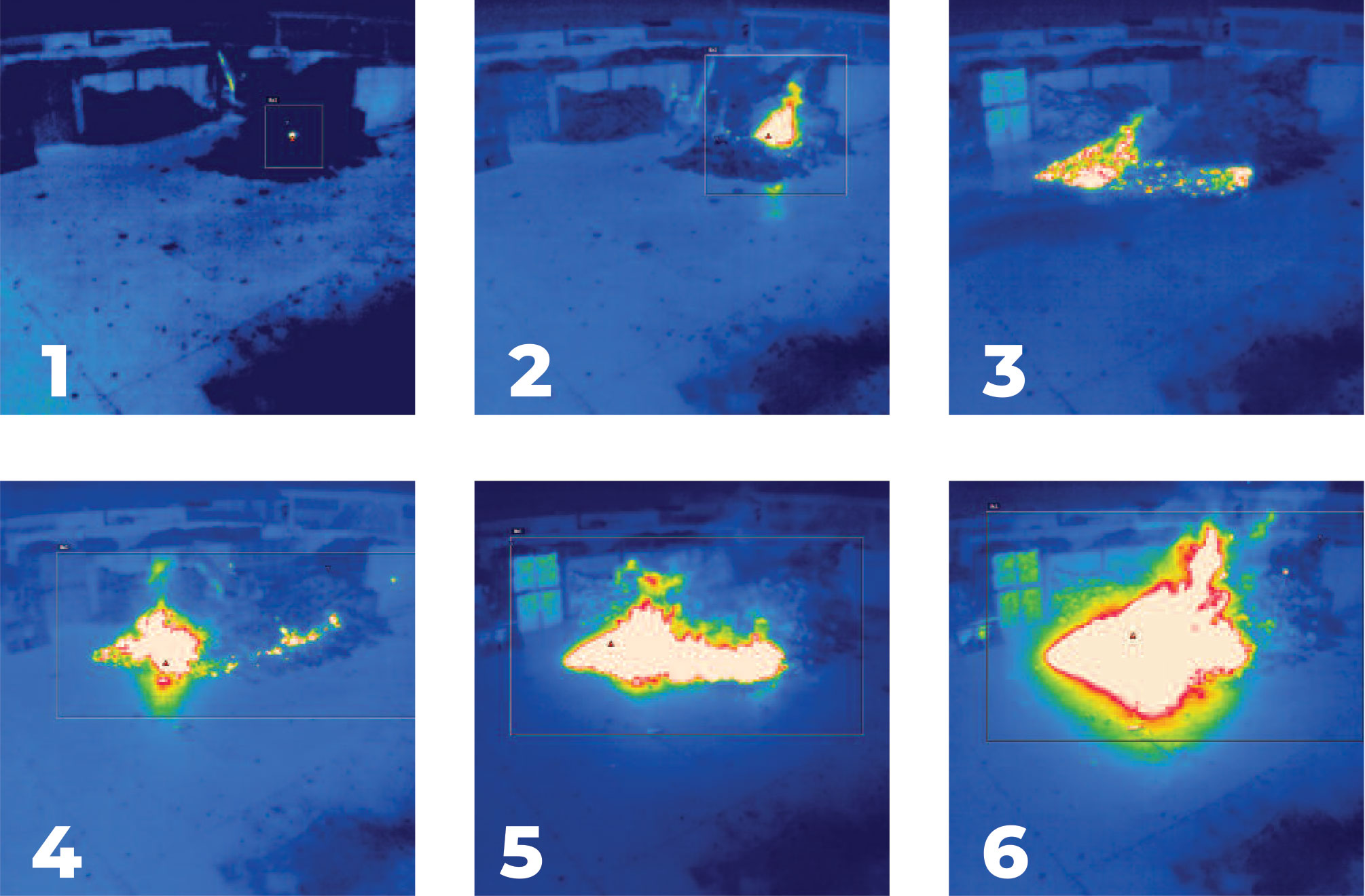

The thermographic early detection system is the only system with which it is possible to promptly identify and recognize signs of ignition before they become significant (photo 1).

Thanks to this “time advantage”, compensatory intervention measures on the monitored area can be considered predictive, making it possible to extinguish ignition early on, before it spreads to other areas or adjacent structures and, therefore, do not require specialized intervention teams to be involved.

Ignition sequence detected by predictive thermography in an outdoor mound of waste

Advantages

- Continuity of operations

- Safeguarding assets and personnel

- Environmental protection

- Protecting the company's image

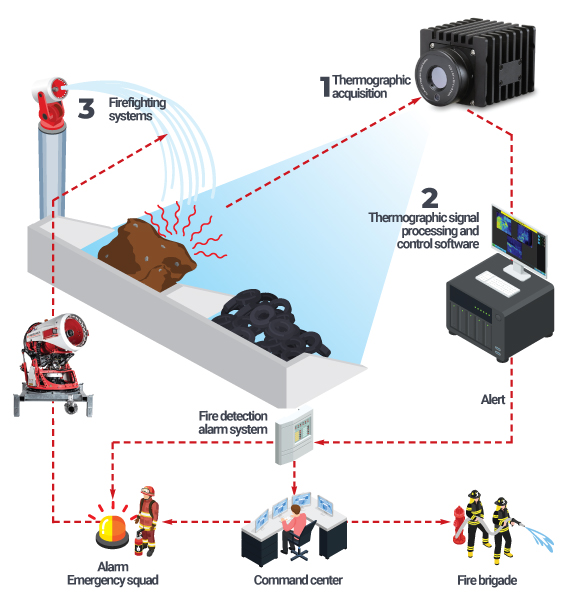

How a predictive thermographic system works

The thermographic system specially developed by Mozzanica for the waste disposal sector consists of three main elements.

Radiometric thermal cameras for image processing, with temperature range, resolutions and specific optics depending on the type of monitoring, which make it possible to recognize – even before ignition – potentially dangerous thermal variations excluding heat sources not related to the process.

Proprietary cloud monitoring and management software that allows simultaneous and centralized control of up to 32 thermal cameras, which are individually set based on the customer’s needs.

Automatic shutdown systems of various kinds depending on the type of plant, or fixed monitors with manual panning or automatic pointing.

The system is constantly connected to an IRAI EN 54 fire control unit linked to a 24/7 command center that is UNI EN 50518 certified, to allow the proper management of alarm transmission procedures and, when necessary, the automatic activation of active protection systems.

The rigorous routine and extraordinary maintenance plans of the entire system, including the necessary and mandatory periodic checks, guarantee the efficiency of the entire fire safety management system.

It's evolved

Mozzanica is able to integrate the thermographic system with its proprietary IoT technology See.iT through which it can offer a remote monitoring and diagnostics service.

Mozzanica is able to integrate the thermographic system with its proprietary IoT technology See.iT through which it can offer a remote monitoring and diagnostics service.

It's universal

The thermographic detection system can be used in any industry or service activity both in firefighting and in the safeguarding of company assets, in the continuity and control of the production process and in preserving the company's image, especially from an environmental perspective.

Mozzanica's know-how in the waste treatment sector is the result of daily discussions with companies that store, treat and transform waste (deriving from the urban recovery cycle, from chemical and pharmaceutical synthesis processes, and the disposal in general of dangerous and particularly flammable waste).

The Mozzanica R&D division is fully aware of the logistical and operational complexities and possible sources of ignition in the sector and is able to provide targeted solutions for risk mitigation in processing and storage areas, and manual and automatic extinguishing systems that guarantee effective management of the fire event starting from its initial phase.

Deluge firefighting systems for enclosed areas

Firefighting systems with mobile hydrants for open areas

Sprinkler firefighting systems for separation hoppers

Automatic pointing monitors for large spaces

Mozzanica's

integrated

solutions

- Thermographic detection

- Fire detection and manual signaling systems

- Automatic pointing monitors

- Sprinkler, water deluge and foam firefighting systems

- Combined water mist or full jet turbines

Mozzanica also provides:

- Firefighting products

- Personal protective equipment

- Man-down devices for lone workers

To complete its services, Mozzanica provides maintenance management of firefighting systems and equipment, remote monitoring in the cloud, and management of the state of alarm and fault status through a certified command center with 24/7 on-call service.